Non Destructive Multi Mate/Demate Metal Seal Formation

Metal gaskets under compression, along a torroidal interface, exhibit plastic and elastic deformation. The elastic deformation is the “spring back” in the gasket indentation that occurs when the fitting is demated. The plastic deformation is remaining the indentation left in the gasket. The elastic deformation is directly proportional to the plastic indention, (i.e. 10%).

As a general rule, in a fitting without torque or galling on the sealing surfaces, the more elastic compression the better the seal. The elastic compression keeps the gas delivery process stream sealed under shock & vibration and thermal cycling.

In regard to legacy face seal fittings, over tightening is a serious concern. According to manufacturers anything past 1/8th turn past finger tight is considered over tight. They caution, “excessive over-tightening will damage the sealing beads and possibly cause system leakage.”

Fittings with torque elimination may be safely tightened up to ¼ turn past finger tight without fear of over tightening.

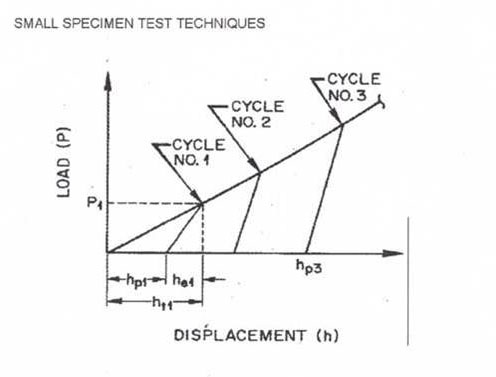

FIG. 5 – Schematic representation of the relationship between indentation load and penetration depth of the ball indenter as observed by increased cyclic loading. Elastic unloading slopes are not parallel because of increased spherical deformation volume as the load is increased.

where

n = strain-hardening exponent, and

K = strength coefficient.

It should be noted that this representation is not a necessary requirement for determining the indentation-derived σl – εp data as will be shown later (Eqs 2 and 3), but it can be used to determine the strain-hardening exponent over the SYM range of interest. Furthermore, a single power curve may not fit the entire SYM curve as noted in ASTM Test Method for Tensile Strain-Hardening Exponent (e-Values) of Metallic Sheet Materials (E 646-78).

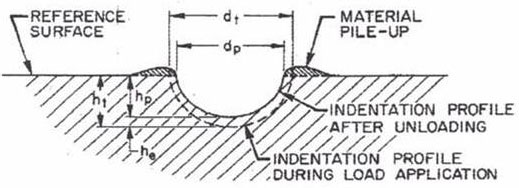

FIG 6 – Illustration of ball indentation geometries before and after load application (the material pileup is exaggerated).